In the modern manufacturing world, where efficiency, precision, and flexibility are paramount, adhesive technology has evolved beyond tradition.

There are many types of adhesives, each with its own curing method. The most common types are adhesives that cure with ambient humidity, solvent-based adhesives that cure when the solvent evaporates, two-component adhesives that cure when mixed with an activator in a specific ratio, anaerobic adhesives that cure in the absence of air, UV adhesives that cure when exposed to UV light, and heat-curing adhesives.

Each method has its own set of advantages and disadvantages. Today, however, we will talk about no-mix structural adhesives, which offer the benefits of both extended open time and fast curing. This type of adhesive initiates polymerisation upon contact with an initiator.

These fast-curing adhesives set quickly when needed without requiring accessories or special equipment. No-mix structural acrylic adhesives also cure on demand.

What are no-mix Structural Adhesives?

No-mix structural adhesives are high-strength adhesives that are activated with a chemical initiator, eliminating the need for mixing. Unlike traditional two-component adhesives, which require the precise mixing of a resin and a catalyst prior to application, no-mix adhesives radically simplify the process. How do they work?

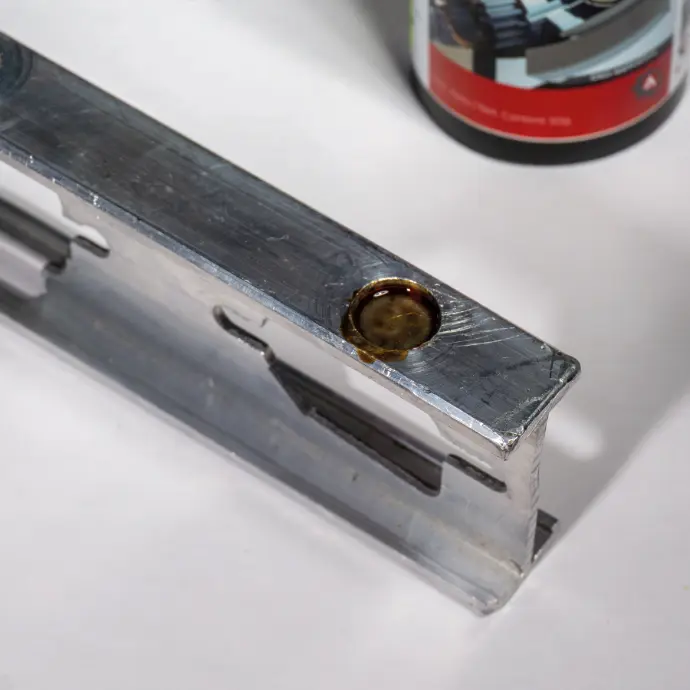

Adhesive is applied to one surface.

The initiator is placed on the opposite surface.

When the pieces are put together, the adhesive cures.

This system eliminates the need for double cartridges, static mixers, pumps, and specialized machinery. This reduces error variables and improves process repeatability.

What is no-mix curing?

It means that the adhesive will not begin to set until it comes into contact with the initiator. This gives operators full control over working time, which is useful for production lines with variable rates and for assembling complex parts that require precise positioning.

How do these adhesives compare to other adhesives?

Bi-component adhesives

-

Advantages: High structural strength, versatility of formulations.

-

Disadvantages: They require precise mixing, special packaging, and dispensing tools.

Cyanoacrylates

-

Advantages: Fast cure time (in seconds) and easy to use.

-

Disadvantages: Short working time, brittleness in certain applications, and difficulty repositioning.

No-mix, adhesives

-

Key advantages:

- No pre-mixing required

- Controlled curing by joining parts together.

- Increased cleanliness and less waste.

- Ideal for automation or manual processes.

Industries

These adhesives have become the preferred solution for attaching magnets and ferrites, particularly in industries such as electric motor manufacturing, audio horn production, precision tooling and electronics, where robust adhesion is required without compromising assembly time or quality.

Electronics industry

Magnets and ferrites assembly

Automotive industry

Machinery manufacturing

Conclusion

No-mix acrylic structural adhesives provide a practical and efficient way to bond high-strength components, eliminating the need for complicated mixing processes, adhesive waste or specialised mixing equipment. Combining ease of use, total cure control and structural performance, these adhesives are the ideal choice for modern industrial processes that demand speed, cleanliness and precision.