ADINOX C50, Methoxyethyl Cyanoacrylate

C50 – Advanced Low Odor, no Blooming Cyanoacrylate for High-Performance Bonding

C50 is a next-generation methoxyethyl cyanoacrylate adhesive engineered to deliver superior performance in demanding industrial applications. Unlike traditional cyanoacrylates, C50 offers low odor and no blooming, ensuring a cleaner, more efficient bonding process without compromising aesthetics.

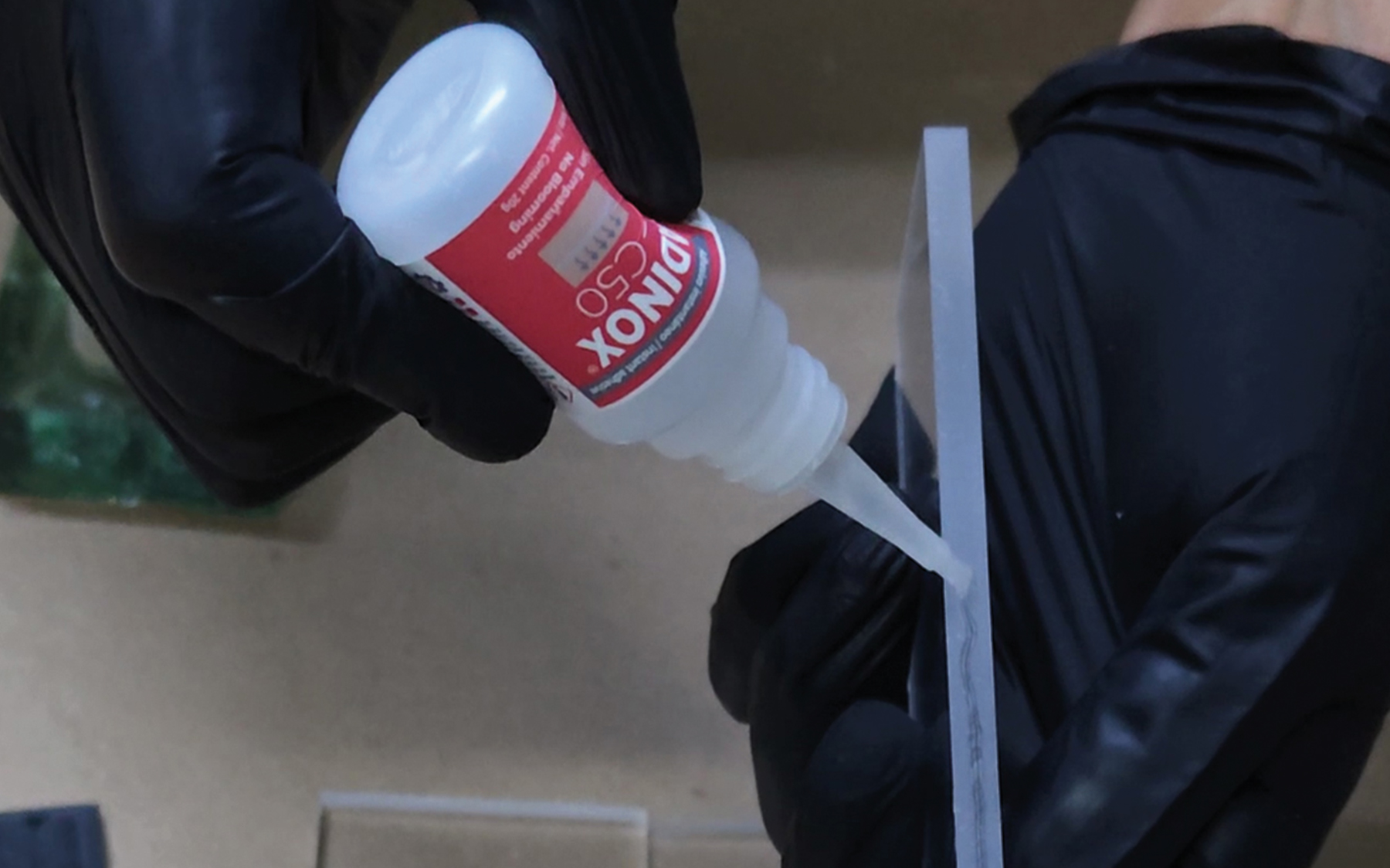

C50's medium viscosity allows for precise application and excellent gap filling, making it ideal for high-precision assemblies. It provides fast, strong and reliable bonds to metals, elastomers and plastics.

Ideal for environments where VOC control is essential, ensuring compliance with strict air quality regulations.

No blooming

Flexible

Low odor and non irritating

What is ADINOX C50?

It is a new generation industrial cyanoacrylate adhesive, ideal for fine, clean and residue-free work in the graphic, advertising and assembly industries.

Substrates

Ideal adhesive for dark or transparent industrial materials, where visual defects are more evident with conventional adhesives.

- Metals: stainless steel, aluminum, carbon steel.

- Thermoplastic plastics: ABS, ASA, acrylic, PET, polycarbonate, PVC and SAN

- Elastomers / Rubbers: Natural rubber, EPDM, neoprene, nitrile, SBR, Viton.

- Composites: Composite panels, fiberglass, carbon fiber.

- Others substrates: Wood, MDF, glass and ceramics.

Industries

Electronics

Optical components

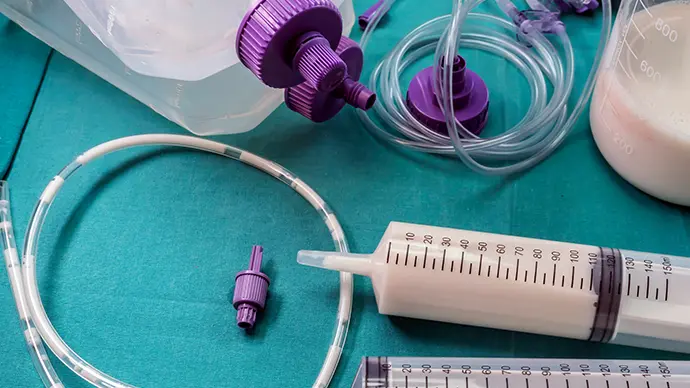

Medical devices

| Color | Transparent |

| Tensile strength | 2,600 - 4,000 |

| Viscosity | 1200 a 1500 cP |

| Gap Filling | 0.30 mm (0.0118“) |

| Blooming | None |

| Maximum Operating Temperature | 80 °C |

| Minimum Operating Temperature | -60 °C |

| Fixture Time | <15 Seconds |

| Tags | |

|---|---|

| Tags | |